Self-Cleaning. Dirt Tolerant.

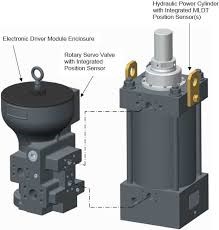

The new industry standard electro-hydraulic linear actuator used in the most demanding environments providing superb accuracy and resolution for stable, reliable and safe operation of steam turbine control valves or valve racks. Used on mechanical-drive or generator-drive steam turbines, the robust design with 50 lbf chip shear force and self-cleaning port design uses a low-pressure hydraulic oil source (typically turbine lube oil) for output shaft force. The V45TT-1507-MUE is an integrated single acting universal mount, fail-extend female-thread shaft actuator for steam and hydro turbines.

Woodward actuator – Varistroke-i – FEATURES & FUNCTIONALITY

Varistroke-I Woodward actuator solves steam turbine users’ #1 reliability problem…dirty oil!

The patented dirt tolerant and self-cleaning technology of Woodward’s Varistroke actuators ensure greater overall reliability of your steam turbine. The Varistroke line of linear electro-hydraulic valve actuators operate mechanical-drive or generator-drive steam turbines. These linear actuators utilize a low-pressure, hydraulic oil source (typically turbine lube oil) to provide output shaft force. Their superb accuracy and resolution make them ideal for steam valve control and related turbine speed and load control, where turbine up-time and availability is essential.

The Varistroke-I line is configurable via a simple user-friendly, computer-based PC service tool, allowing users to easily configure, calibrate, and adjust all internal functions and response settings. Its integrated driver includes a 4-20 mA output channel to indicate output shaft (control valve) position, as well as unit alarm and shutdown relay outputs for use as unit health and status indications. The 4-20 mA demand inputs and dual-redundant shaft position sensors allow it to continue to operate even with demand input or feedback sensor failures, ensuring extended run-times between forced outages and on-line system repair.

The total installed cost for this fully integrated Woodward actuator is low because it is completely assembled and tested at the factory, greatly reducing OEM and end-user fabrication, testing, and site assembly time. In retrofit applications, the Varistroke-I actuator can be used to directly replace the existing servo system. This saves costly repairs to existing and aging servos, eliminates the difficulty of obtaining spare parts for obsolete equipment, and reduces calibration time and difficulty.

Dirt-tolerant design:

- Two moving parts

- 50 lb chip shear force

- Self-cleaning valve design

Fast slew rates/times:

- Application dependent

- Slew rate up to 762 mm/s (30 inches/second) @ 500 psi supply pressure no load

Side-load tolerant:

- Shaft bearings

- Triple seal technology

Integrated driver:

- 4–20 mA

- Included valve flow linearization table

- Variable / configurable shaft stroke lengths

- Precise position control

- Redundant MLDT position sensors

- Certified for Hazardous Locations

Please access our Woodward technical library here. We’ll continue to add valuable technical information and project information to our Resources & info Page.

https://youtu.be/QITajvzd9xw